Includes: Moulding, Etching, Hot Embossing, Roll-to-Roll, 3D Printing.

Entries from Microfluidics Consortium Members

Eden Tech

In the heart of France’s vibrant scientific community, Eden Tech is pioneering a revolution in microfluidics, driving groundbreaking advancements in research, scale-up capabilities, and a diverse array of innovative solutions. Our team of passionate experts is dedicated to unlocking the immense potential of microfluidics, transforming this cutting-edge technology into a powerful tool for addressing some of society’s most pressing challenges.

Our expertise lies in developing innovative microfluidic platforms that enable researchers to perform precise and controlled experiments with minimal sample consumption. This enables scientists to conduct groundbreaking research across a wide range of disciplines.

France boasts a rich heritage in scientific research and technological innovation, making it an ideal home for Eden Tech. Our location in Paris, a global center for scientific excellence, provides us with access to a network of leading research institutions, talented engineers, and a supportive entrepreneurial ecosystem.

Join us in shaping the future of microfluidics. At Eden Tech, we are passionate about harnessing the power of microfluidics to address global challenges and improve the lives of people around the world. We invite you to join us on this journey of innovation by exploring our website or collaborating with us on your research endeavors

FEMTOprint

FEMTOprint is a Swiss high-tech company manufacturing transformative 3D microdevices out of glass and other transparent materials. Certified ISO 13485:2016, the FEMTOPRINT® technology allows to develop multi-functional devices combining fluidic, mechanical and optical features in single monoliths, with sub-micron resolution.

Besides free-form manufacturing, the platform integrates other advanced treatments like surface polishing, metal ablation, surface functionalization, optical patterns in the bulk and hermetic glass-to-glass welding, making the FEMTOPRINT® technology the most industrialized 3D micromanufacturing process, whether you are considering rapid prototyping or volume production.

With laser exposure, we create optical paths and draw 3D shapes. The overall process resolution can be better than 1 µm. The aspect ratio can go up to 1:1000, depending on the material. After machining, the standard roughness of the parts is around Ra 70-200 nm, to be reduced below Ra < 10 nm with a contactless polishing process.

Application: Flow cells – Droplet generators – Nozzles – Lab- and organ-on-a-chip – Masters for mould replication -Drug delivery systems -Microreactors -Implantable devices -Surgical tools

HiComp

Established in 2014, HiComp Microtech stands as a premier original design manufacturer specializing in advanced microfluidics products and laboratory consumables. Our solutions boost precision, efficiency, and reliability from prototyping to mass production. Quality, performance and affordability are our priorities.

Leister

Fluidic Components Welding with Laser Welding Systems from Leister

The areas of application are diverse, whether gases or liquids, the main thing is that the weld is tight and meets the requirements. The laser welding processes from Leister used are based on the design of the components and their production requirements. Laser welding from Leister is particularly suited to the requirements of microfluidics. Here, the areas between the fluidic channels must be hermetically sealed without contaminating the channels themselves. Complex structures with long weld seams and varying sizes can be ideally welded with mask welding from Leister – a mixture of contour and simultaneous welding. With this technique, welding times can be reduced many times over compared to contour welding. Compared to other joining methods such as adhesive bonding, laser welding saves production steps, material and storage costs.

Philips MEMS Micro Devices MMD

We design, develop and manufacture custom microelectromechanical systems (MEMS) and assemble non standard micro devices. We have 150 experts working at the ISO 13485 qualified MEMS Thin Film Foundry and Micro Devices Facility. We offer MEMS prototyping, process development, manufacturing, as well as Micro Devices and assembly services

z-Microsystems

Engineering & micro mould design

Our team supports customers from the development phase with their experience as well as with simulation analysis

Optimization of the fluidic design in terms of producibility (design for manufacturing)

Flexible and innovative mould solutions to assist our customers during their development steps

First sampling and pre-production, testing of different resin material and determining the most efficient moulding process

Assurance of the required quality by testing according to certified QC protocols

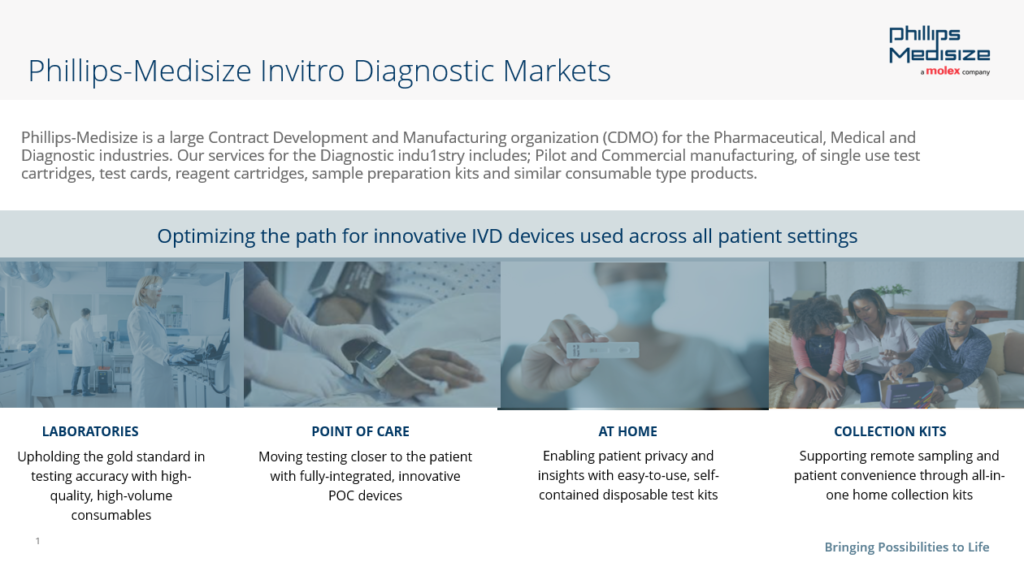

Phillips-Medisize

Our core services include:

- Injection molding (including micro-fluidic channels)

- High and low volume assembly of test cartridges and consumables

- Sourcing of injection molds, assembly equipment and purchased parts e.g. filters, Pressure sensitive tapes, plastic films, desiccants, etc.,

- Onboarding of chemicals including reagents, lyophilised beads

- Functionalisation of plastic substrates

- Final packaging

SuSoS “Because Surface Matters”

Emulseo

Other Non-Member Entries

All Consortium Member Bio Sensors Connectors Fluid Flow Components Manufacturing Technologies Microfluidic Chips Process Equipment R & D Services Diagnostic Devices Organ on a Chip DNA Synthesis Non Health