Members of the Microfluidics Consortium

MicrofluidX

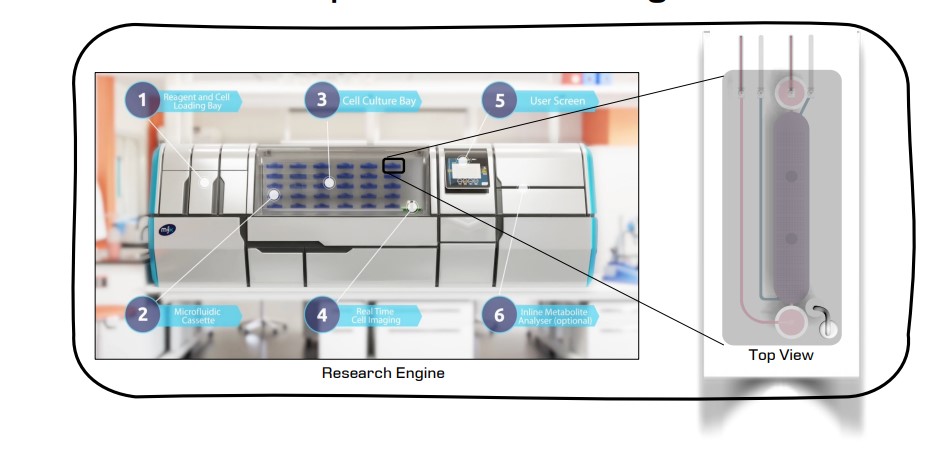

environment from process development to cell manufacturing. The engine provides multiple

independent end-to-end experiments in high-precision, low-volume perfusion bioreactors

coupled with online cell imaging, count, pH, dissolved oxygen and metabolite analysis.

These bioreactors are closed chips based on micro-/meso-fluidics technology. Miniaturisation

of environments for cell culture have proven to be more effective in finely controlling fluid

processes and nutrient concentrations. Cell culture for cell therapy manufacturing

applications involves numerous bioprocesses, and MicrofluidX’s bespoke patent-pending

design accommodates and maximises each process in an end-to-end manner from seeding

(for homogeneous distribution) to cell selection (for increased purity) to transduction (for

efficient gene transfer) to expansion (for cell proliferation) and sampling/harvest (for high

recovery).

Non-member links