UpNano

UpNano’s two-photon polymerization (2PP) 3D printing technology enables precise fabrication of complex microfluidic and organ-on-chip platforms with sub-micrometer resolution.

The NanoOne 2PP printer’s ability to print directly inside microfluidic chips, combined with biocompatible materials fully optimized for the platform like HYDROBIOINX® U200, allows the integration of vascular-like channels, membranes and tissue scaffolds essential for physiological modeling. This precision supports the fabrication of realistic organ-level microenvironments for drug testing and disease modeling, accelerating the shift toward animal-free testing and personalized medicine.

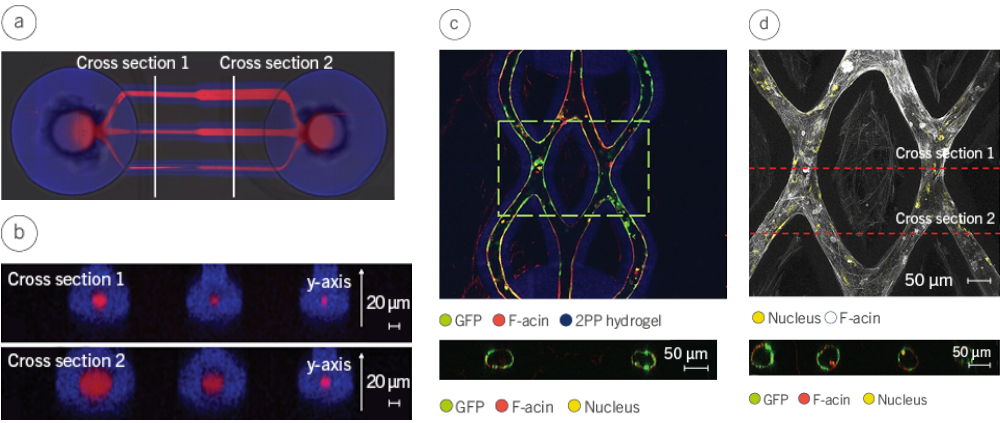

A case from Cantoni et al. exemplifies the impact of the NanoOne through their introduction of a custom microfluidic chip to create perfusable microvessels through a two-step method. Their approach enables the rapid creation of 10 μm channels, as shown in Figure a & b, significantly faster than printing the entire construct. Confocal images showcase the formation of a human umbilical vein endothelial cell (HUVEC) monolayer alongside the microchannels, as shown in Figure c & d [1]. Overall, this approach exemplifies how smart fabrication techniques can boost MPL capabilities for creating microphysiological models.

Figure: a, Top view and b, cross section of a MPL fabricated channel structure after 10 days, with diameters of 30, 20 and 10 μm for cross section 1 and 60, 40 and 20 μm for cross section 2. MPL printed structure in blue and Antonia Red-dextran in red. c, Overview, d, zoomed-in and respective cross-section image of human umbilical vein endothelial cells (HUVECs) and fibroblasts lining the MPL printed microchannels. Adapted from [1], CC BY 4.0.

Citation: [1] Adapted from F. Cantoni, L. Barbe, H. Pohlit, M. Tenje, A

Perfusable Multi-Hydrogel Vasculature On-Chip Engineered by 2-Photon 3D

Printing and Scaffold Molding to Improve Microfabrication Fidelity in

Hydrogels. Adv. Mater. Technol. 2024, 9, 2300718.

https://doi.org/10.1002/admt.202300718